Glass adhesive glue, while seemingly mundane, is an indispensable tool in both our everyday lives and various industries. Its importance can’t be overstated. In this comprehensive guide, we will embark on a journey exploring the types, applications, and nuances of glass adhesive glues.

Let’s get started!

Glass Adhesives: Overview

The history of adhesives dates back thousands of years, with early civilizations discovering the benefits of natural resins and gums to bond different materials together. In the context of glass, the journey of adhesives has been particularly fascinating.

Ancient uses and early innovations: The earliest known adhesives for glass can be traced back to ancient Egypt. Around 1500 BC, Egyptians employed animal glues to bond glass beads onto various objects.

Such glues were derived from collagen, which is found in animal bones and hides. In Roman times, natural resins like birch bark tar were used as a binding agent for glass and other materials.

Types of Glass Adhesive Glues

In the vast realm of adhesives, the kind you choose is dictated largely by the task at hand. With a focus on glass as the primary substrate, there are distinct types of glues that are favored for their particular attributes.

UV-cured Adhesives

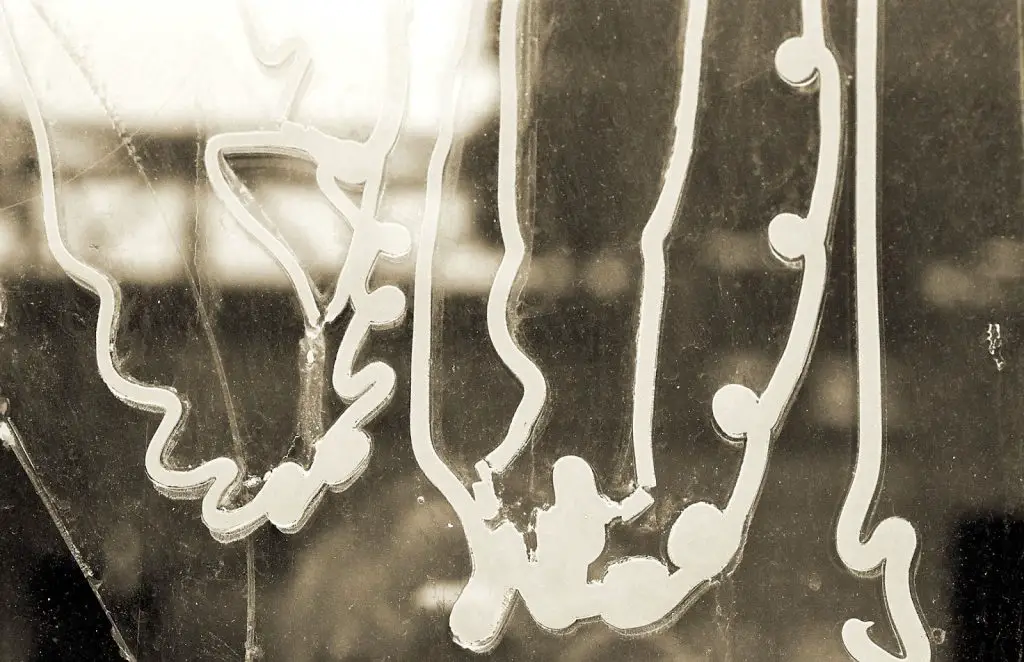

UV-cured adhesives are a marvel of modern adhesive technology. They are designed to solidify or “cure” upon exposure to ultraviolet light. Features of UV-cured adhesives include rapid setting times, transparency, and robust bonding strength. They offer a non-yellowing bond, which is crucial for applications demanding clarity.

Their main uses encompass areas where quick bonding is essential, such as in the optical industry for lens bonding, decorative glass designs, and even in dentistry for certain dental procedures. Moreover, their transparent nature makes them an optimal choice for decorative glass items and clear glass fixtures.

Epoxy-based Adhesives

Epoxy-based adhesives are two-part systems, consisting of a resin and a hardener, that when mixed together, initiate a chemical reaction resulting in a hard, durable bond.

Pros of using epoxy-based adhesives include its exceptional bonding strength, ability to bond a vast range of materials beyond just glass, and resistance to chemicals and high temperatures.

However, there are also cons. They typically take longer to cure than UV adhesives, sometimes requiring clamping of the bonded materials. Additionally, they can become brittle over time, and their bond may yellow or cloud under prolonged UV exposure.

Silicone-based Adhesives

Silicone-based adhesives, derived from siloxane polymers, are known for their flexibility and resilience. They boast an excellent temperature range, retaining their properties even under extreme conditions.

These adhesives are particularly resistant to moisture, making them a prime choice for outdoor applications. Where they’re commonly used is in areas demanding a flexible yet strong bond.

This includes aquariums, due to their water-resistant properties, window sealing, because of their weatherproofing capabilities, and even in the automotive industry for bonding parts exposed to varying temperatures.

Factors to Consider When Choosing a Glass Adhesive

Various factors come into play, ensuring that your bond lasts and serves its intended purpose effectively. Consider the following:

Surface Type

The diversity in glass types—from tempered to laminated or even textured—requires different adhesive characteristics. It’s imperative to match the adhesive to the glass type.

For instance, UV-cured adhesives might work best for clear, non-textured surfaces due to their transparency, while silicone-based adhesives might suit textured or frosted glass better because of their flexibility and gap-filling capabilities.

Drying Time

Adhesive drying times can vary drastically. Quick-set adhesives, like UV-cured types, offer immediate bonding, essential for industries or applications where time is of the essence.

However, the rapid setting leaves little room for repositioning. On the contrary, slow-drying adhesives, like certain epoxies, allow for adjustments but require patience and sometimes clamping. It’s a trade-off between speed and flexibility.

Durability & Strength

While an adhesive’s immediate bond strength is crucial, its longevity and load-bearing capacities are equally significant. It’s essential to opt for adhesives that resist environmental factors like UV rays, moisture, or temperature fluctuations, ensuring the bond remains intact over time. Some applications might demand high tensile strength, making epoxy adhesives a preferred choice.

Top Brand Recommendations

- Gorilla Glue: Known for its expansive product range, Gorilla Glue’s glass adhesive is revered for its strong bond and versatility. Highlighted features include its waterproof properties and the ability to bond to more than just glass. It’s also paintable and stainable, making it a favorite for DIY enthusiasts. The brand’s main selling point is its promise of an “incredibly strong” bond.

- Loctite: Another behemoth in the adhesive industry, Loctite’s glass glues are known for their precision and durability. When compared to other brands, Loctite often gets lauded for its resistance to high temperatures and chemicals. Their products are designed with user-friendliness in mind, featuring easy-to-use applicators and clear instructions.

- 3M: A brand that resonates with industrial professionals and household users alike, 3M’s adhesives are backed by rigorous research and testing. Their glass adhesives, in particular, stand out for their longevity. Specialized uses include automotive and architectural applications, with numerous testimonials praising their bond strength and durability. 3M’s reputation for innovation also means users can expect products that are at the forefront of adhesive technology.

Applications of Glass Adhesive Glues

Glass adhesives’ unique properties cater to a plethora of applications, making them indispensable in many spheres of life.

Household Applications

Within our homes, glass adhesive glues come to the rescue in numerous scenarios. From DIY projects, like creating personalized glass decor, to essential repairs such as fixing a broken vase or mending a detached window pane, they’re the unsung heroes. Beyond these, their everyday uses include sealing glass cabinets, attaching hooks to mirrors, or even fixing glassware.

Industrial Applications

In industries, the scope of glass adhesives expands exponentially. The automotive sector utilizes them for windshield installations, ensuring durability and safety. In construction, they play a pivotal role in installing glass panels or creating sealed windows.

Other sectors, like electronics, rely on these adhesives for screen bonding, while the aerospace industry values them for their strength and lightweight properties.

Safety and Precautions Before Use

Handling chemicals, even those used daily, necessitates caution. Glass adhesive glues, while user-friendly, require certain safety measures to ensure optimal results and personal protection.

Handling and Storage

To maintain the efficacy of your adhesive, storing it correctly is essential. Most adhesives should be kept in a cool, dry place, away from direct sunlight. Ensure the cap or nozzle is tightly sealed to prevent air ingress, which can cause the glue to harden prematurely.

For two-part adhesives, always keep the components separate until ready for use. And, always check the expiration date before application, as old adhesives can lose their bonding capabilities.

Application Safety

When using adhesives, personal safety should be paramount. Always work in a well- ventilated area to avoid inhaling fumes. Wearing protective gear, such as gloves and safety goggles, prevents skin and eye contact. And, always keep adhesives out of children’s reach.

Disposal and Recycling

Proper disposal of adhesive containers is crucial. Empty adhesive containers should be disposed of according to local regulations. Some containers may be recyclable, depending on the material and local recycling facilities.

As for leftover adhesive, never pour it down the drain. Instead, let it harden and dispose of it as solid waste. Remember, being informed about disposal methods ensures both environmental protection and personal safety.

Troubleshooting Common Issues

Every tool or product, no matter how efficient, can pose challenges, and glass adhesive glues are no exception. While they promise robust bonding and longevity, users might occasionally face issues. Recognizing these problems and understanding their root causes can pave the way for effective solutions.

- Weak Bonding

Causes: Insufficient surface preparation, using expired or inappropriate adhesive for the glass type, or not following the manufacturer’s instructions can lead to weak bonds.

Solutions: Always clean and, if necessary, sand the surfaces before application. Ensure you’re using the correct adhesive for your specific glass type and follow the application instructions meticulously.

- Yellowing or Discoloration

Causes: Prolonged exposure to UV rays, using low-quality adhesives, or certain chemical reactions can cause adhesives to yellow over time.

Solutions: Opt for UV-resistant adhesives if the bonded item will be exposed to sunlight. Investing in higher quality adhesives can also reduce the risk of discoloration.

Conclusion

Glass adhesive glues, though small in stature, play a monumental role in our daily lives, from our homes’ aesthetics to vast industrial applications. The journey of selecting the right adhesive underscores the importance of informed choices, ensuring both durability and aesthetics.

As we’ve explored, understanding the nuances, from types to applications and challenges, can make all the difference. Equally paramount is our responsibility towards safe usage and environmental consciousness.